How to catch a jet of water

A waterjet can be a versatile tool. A wide variety of materials such as rubber, paper, glass, stone or metal can be precisely processed by waterjet cutting. Because the process does not heat the material, the properties of the material are not processed either, which offers a great advantage over other cutting processes. However, it is difficult to machine hollow bodies such as pipes when only part of the body must be machined, but other areas must not be damaged. The water jet is diverted during the cutting process and can cause damage inside the hollow body that is not desired.

In the AbWaHo project - Absorbers for Waterjet Machining of Hollow Bodies - ifw Jena is therefore working on the development of an absorber system for waterjet cutting. The aim is to protect the inner walls of pipes or hollow bodies and, at the same time, to guide water scattered back from the absorber in such a way that it does not affect the cut surfaces of the workpiece.

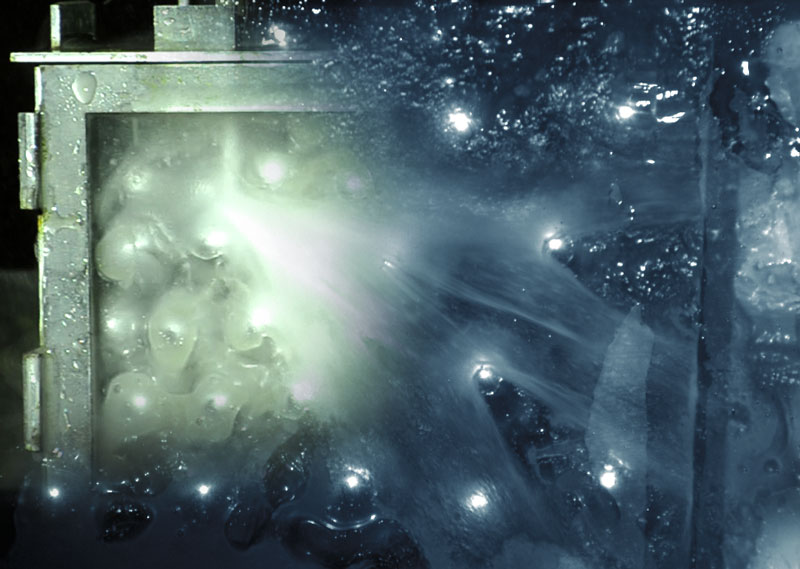

To this end, the project is investigating how the water jet is deflected and redirected during the cutting process of various materials. In a specially developed trainer, high-speed cameras are used to observe how the jet would strike the workpiece and continue inside the hollow body during cutting. The recordings provide insights into the behavior of the waterjet with different materials. This knowledge is then used to develop an absorber system that "catches" the jet in a material-specific manner to prevent damage to the interior of the component or its cutting edge.

Such an absorber system extends the industrial use of waterjet cutting as an inexpensive and effective cutting process.

The project is funded by the German Federal Ministry of Economics and Climate Protection in the INNO-KOM program.