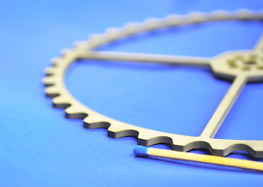

WATERJET CUTTING

ifw Jena offers the separation process of abrasive waterjet cutting. With a beam thickness of one millimeter, we can cut very filigree and nested structures.

The advantages over the laser beam cutting or other abrasive separation processes are the cold processing of the material, which avoids deformations, the high quality of the cut and the low loss of material due to the thin water jet. Another advantage is that materials with a thickness of up to 50 mm can be easily cut according to the customer's requirements.

With our systems we are able to precisely process a variety of materials :

- Steels

- Glass, ceramics

- Aluminum alloys

- Copper alloys

- Tungsten, molybdenum, titanium, silicon

- Glass/carbon-fiber reinforced plastics (GFRP/CFRP)

- Stone, ceramics, tiles

- Plastics of all kinds

- Sealing materials (rubber, plastics with inlays or similar)

- Composite material (laminated safety glass, metal-plastic)