DIFFUSION BONDING and processes of heat treatment

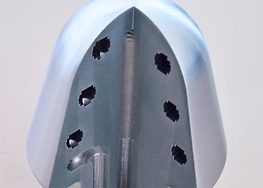

Diffusion Bonding has increasingly proved to be the welding technique most suited for obtaining large-scale, pressure-resistant and vacuum-tight welding joints which exhibit both a high durability and a high sustainability.

Similar to Additive Manufacturing, this welding technique is capable of producing multi-layered monolithic components or semi-finished products with internal hollow structures, which are impossible to achieve through any of the so far established machining technologies.

Among other things, Diffusion Bonding also allows for substance-to-substance bonding of materials which are either difficult or impossible to solder. Our research examines the thermo-mechanical behavior of materials, as well as the influence of surface topography and oxide layers on the process. Furthermore, we investigate experimental bonding processes – such as FEM-Simulation and Welding Parameter Qualification. We also provide the analytical assessment of the resulting welding joints by means of destructive and non-destructive material testing processes.

Our research concentrates on the following materials:

- Copper and copper alloys

- Aluminum and aluminum alloys

- Low- and high-alloy steels, high-strength steels

- Precious metals

- Silica glass, borosilicate glass, chalcogenides, optical glasses

- Machinable glass ceramics with low thermal expansion

- Oxide and non-oxide ceramics

- Crystals (e.g. sapphire, laser materials)