Up and down in laser welding – investigations into vertical beam oscillation

The so-called wobbling of the laser, i.e. the oscillation of the beam in a horizontal direction, has already established itself as a means of producing high-quality welded joints. This method ensures better gap bridging in particular. Vertical beam oscillation, on the other hand, is a relatively new way of optimizing laser weld seams.

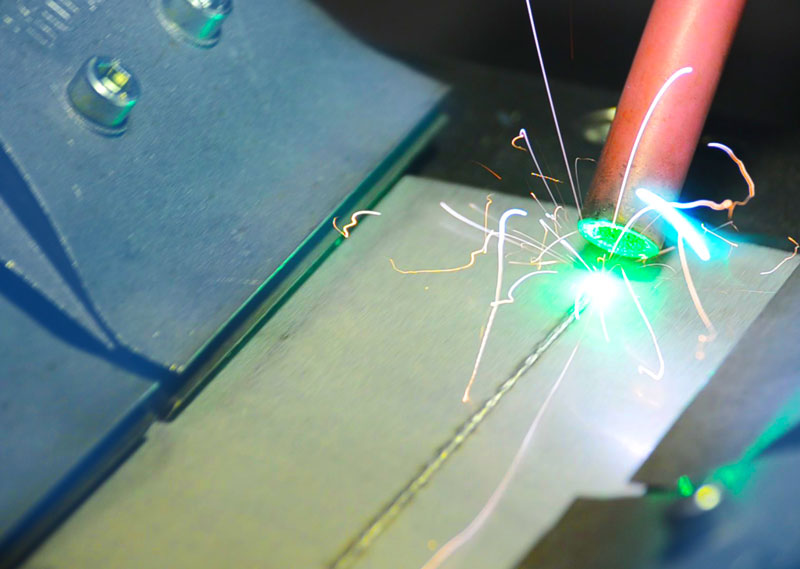

Together with the company ROBUST AO, ifw Jena is investigating laser beam welding with vertical beam oscillation in the Dynasti project - dynamic beam oscillation in the Z direction. Weld seams are produced on blind seams and butt joints of structural steel and aluminum alloys. The tests are carried out with oscillating movements of the laser beam at different intensities and monitored using high-speed recordings with the support of OSCAR PLT GmbH. Based on the high-speed recordings of the welding process, optimum process parameters are to be found for the various materials and sheet thicknesses in order to produce high-quality laser weld seams at the highest possible speed.

In the project, the thermomechanical and weld pool dynamic properties in particular are being observed, which allow conclusions to be drawn about spatter and pore formation in and around the weld seam. The investigations, which will be carried out at ifw Jena until the end of March 2024, are intended to make laser welding processes even more economical for companies. The research results will enable companies to efficiently weld thicker sheets with lasers, even on highly reflective materials such as aluminum.

Video of the examinations on LinkedIn

The project is funded by the Federal Ministry for Economic Affairs and Climate Protection in the INNO-KOM program.