Optimale 3D-Druck-Oberflächen für den Feinguss

3D printing processes are actually ideal for complex models with individual structures. However, the rough surfaces of additively manufactured parts, the “staircase effect” caused by the layer-by-layer construction, and possible residues from necessary support structures can cause significant impairments when used later for investment casting tools. This is where the Opti3D project comes in, in which FDM processes with various materials are to be further optimized at ifw Jena.

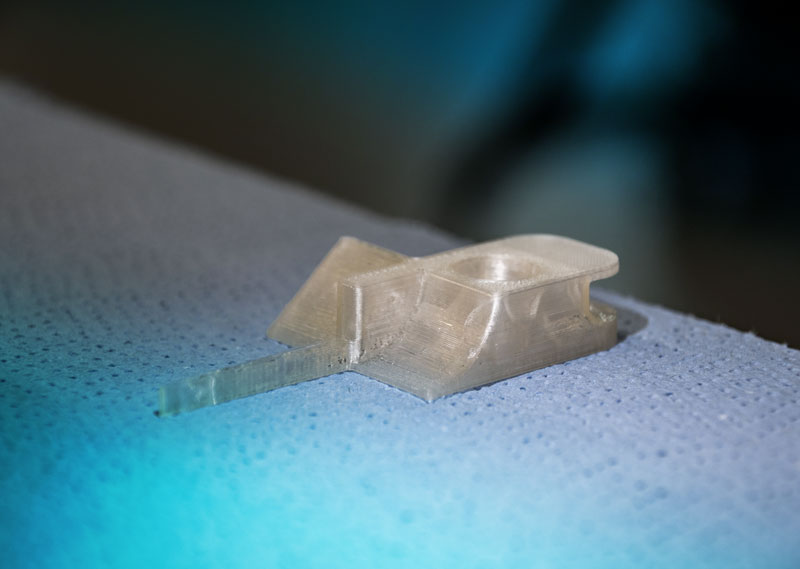

The project is investigating the processability of various plastics used for lost models in additive processes. Process parameters are being determined using test geometries from our project partner Portec GmbH in order to optimize the FDM process for the specific plastics. The test components are designed in such a way that they reflect real lost models on the one hand, but on the other hand pose challenges to the manufacturing process due to their design.

The 3D-printed molds are then tested in the project according to various specifications. This involves examining the residual ash content after combustion, how dimensionally stable the molds can be manufactured, and how the surface quality can be improved during printing as well as through subsequent chemical polishing.

The aim of the project is to determine suitable plastics, ideal process parameters, and the right post-processing steps for different mold geometries. The project results should help companies to manufacture lost molds as cost-effectively as possible and to be able to easily adapt the mold geometries.

The project, funded by the Free State of Thuringia, was co-financed by the European Union under the European Regional Development Fund (ERDF).