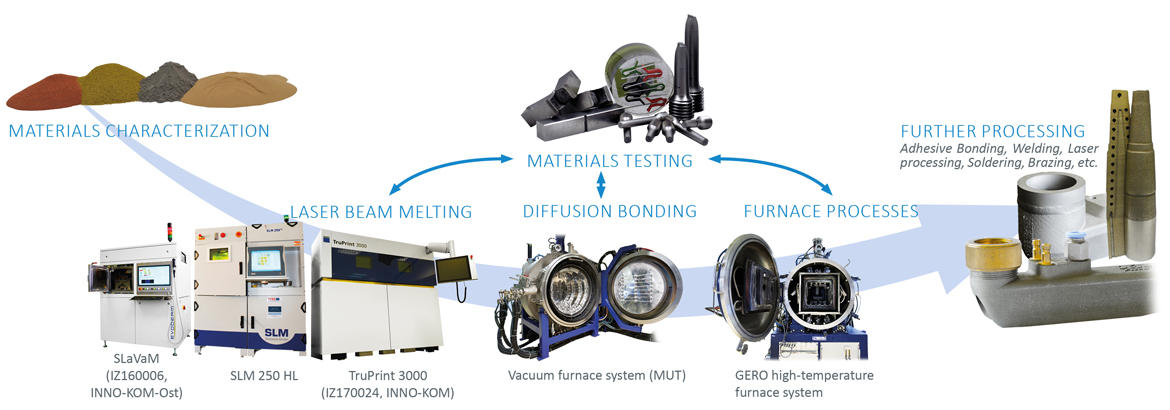

MATERIALS TESTING of additively manufactured parts

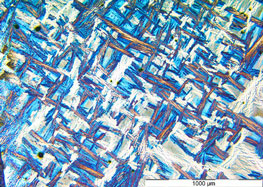

Particularly in the case of additively manufactured components, there are many special requirements for test methods and interpretation of results. Relevant parameters such as grain size, microstructure, construction direction, installation space orientation and laser parameters used make the material testing of metallic additively manufactured parts particularly complex.

At ifw Jena, we cover the entire process chain of additive manufacturing. From powder qualification to process-appropriate construction and the construction process to quality assurance and material testing of the finished parts, we carry out all process steps in-house.

With our expertise, we support you in the qualification of new materials as well as in the quality assurance and testing of your additively manufactured components.

Testing methods for additive manufacturing

Destructive testing

- Tensile and pressure testing up to 500 kN

- Tensile and pressure test from -70 °C to 350 °C (not accredited)

- Impact bending test up to 300 J and from -60 °C to room temperature

- Hardness test after

Brinell (HBW)

Rockwell (HRC)

Vickers (HV0.01 to HV30) - Fatigue tests (not accredited)

- Emission Spectroscopy (OES)

Non-destructive testing

- Radiographic examination RT

- Computed Tomography CT (not accredited)

- Scanning Electron Microscopy (SEM) with Integrated Element Analysis (EDX)

- X-ray fluorescence analysis (RFA) (not accredited)

- Metallography (eg microstructural investigations) (not accredited)

- Surface testing (roughness, topography) (not accredited)

Over many years of research at ifw Jena in the field of additive manufacturing, our materials testing laboratory specialized in the testing of metallic 3D-printing components. Among other things, since 2013 we have been actively contributing to the implementation of VDI proficiency testing in the context of the VDI Guideline 3405 and are represented in numerous networks and committees dealing with topics of additive manufacturing processes. These include, among others, FA 13/DVS, VDI FA 105 or the DIN Materials Technology Standards Committee "Additive Manufacturing".