SOLDERING AND BRAZING

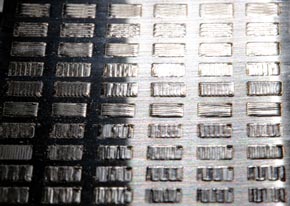

Furnace Brazing

Furnace brazing can be accomplished in three different environments: vacuum, a protective gaseous atmosphere or open air. The following filler materials can be employed in the process: metal brazes (flux coated and bare), active metal brazes, reactive air brazes and solder glass (with normal furnace atmosphere). A decisive advantage of furnace brazing is the even heat distribution within the workpiece. In this way, the temperature gradient remains low throughout the entire brazing process wherefore stress within the component is minimized.

A great variety of similar and dissimilar materials (e.g. glass/ceramic, metal) can be joined by means of furnace brazing under consideration of their specific coefficients of thermal expansion.

Dipl.-Ing. Susanne Kasch +49 3641 204-139 E-Mail schreiben

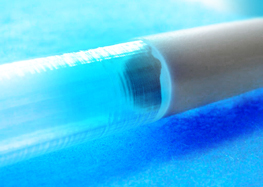

Laser soldering and brazing

Apart from conventional furnace brazing, laser soldering and brazing are important fields of research at ifw Jena, especially in connection with procedures for joining glasses, ceramics and sapphire.

Our work focuses on the development of strategies for processes which require a locally and temporally restricted channeling of energy and heat into the joint zone (e.g. encapsulation of temperature-sensitive components). The localized energy input is always case-specific and is essential for ensuring stress minimization within the joint zone.

Comprehensive procedures -regarding control, measurement, beam shaping and assessment- have been designed to increase the reliability and reproducibility of application-related process investigations.

Our research activities in this field address the following topics:

- thermo-mechanical material behavior

- wetting capacity (material surface)

- soldering and brazing parameters

- analytical evaluation of resulting joints through destructive and non-destructive material testing methods

The following materials are being analyzed for this purpose:

- titanium, copper, hard metals, alloy steels, low thermal expansion materials (e.g. invar, kovar)

- oxide and non-oxide ceramics, glasses and sapphire

- glass-metal composites and metal-ceramic composites

- metal and active metal brazes, reactive air brazes

- crystallizing and composite solder glasses

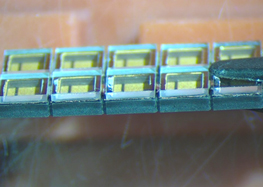

Recent Projects in the field of soldering and brazing

Ceramic H₂ sensor development of a ceramic pressure sensor platform for hydrogen management of the industrial materials management of the future.

more