ULTRA SHORT-PULSE LASER PROCESSING

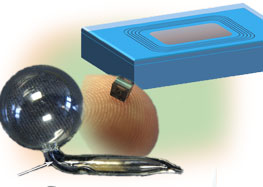

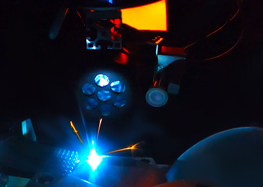

Laser systems operating with light pulses of a length of a few picoseconds or less are known as Ultra Short Pulse Laser (USP-laser). Due to their extremely high peak intensity, laser pulses of such short duration give access to unique fields of application

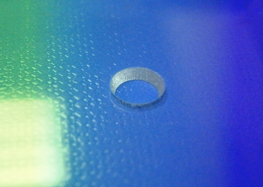

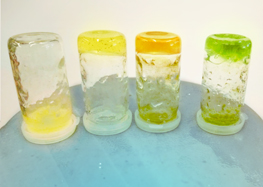

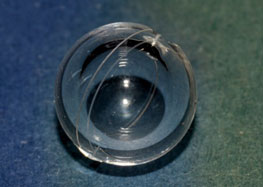

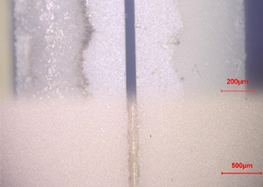

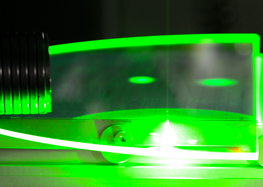

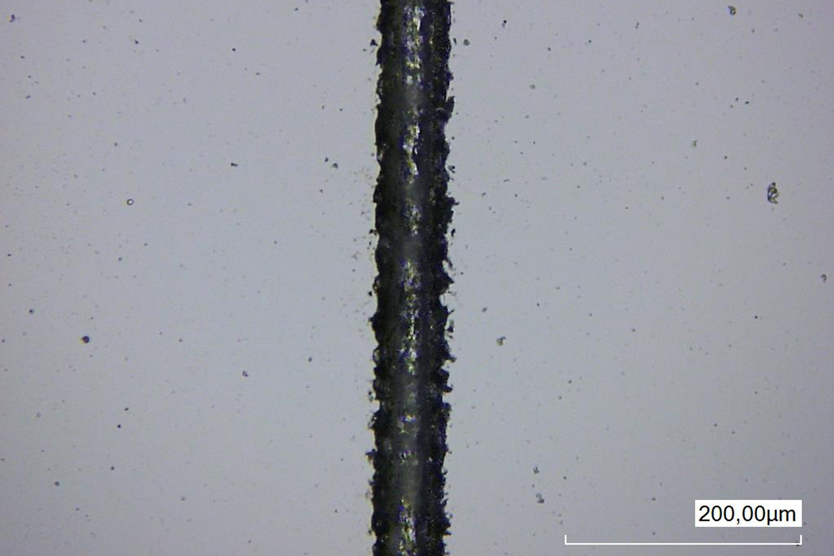

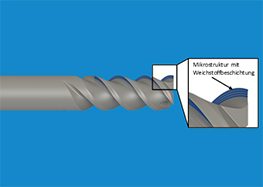

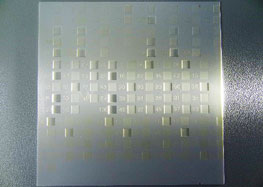

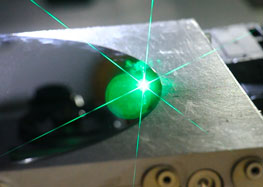

Other than conventional laser systems, which melt and vaporize the processed material, USP-lasers destroy only its chemical bonding. As a result, they produce clean machining edges and only a minimal thermal stress on the surrounding surface. The high pulse energy ensures the absorption of the laser beam in the laser focus point alone. This characteristic also allows the processing of materials, which are transparent to the laser wavelength. Additionally, the USP-laser technology makes internal processing of transparent materials possible without inflicting any damage to the surface of the workpiece.

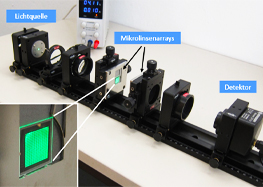

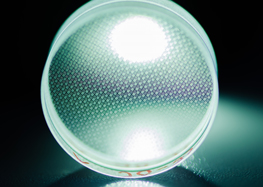

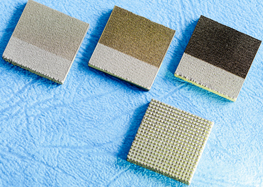

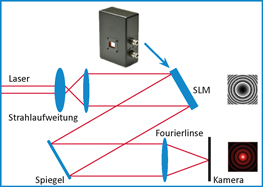

The research conducted at ifw Jena in the field of USP-lasers focuses on the processing (i.e. on scribing, drilling, welding and surface modification) of brittle and hard materials such as ceramics and glasses. In addition, parallelization strategies are being developed in order to make use of the high output powers of modern USP systems up to the kW range.

Our equipment for USP-laser material processing includes: galvoscanners, linear and rotation-axis systems, trepanning optics, modules for wavelength conversion to the second and third harmonic, as well as sensors, cameras and microscope objectives for the measurement and positioning of workpieces.